‘Tactile fields’

A tactile, interactive and reconfigurable installation serving as urban space for meditation, relaxation and atmospheric therapy.

‘FY-langes’ project - proposed as part of the Fast-Pace Slow-Space Seminar at Columbia University.

Special Mention in the Architizer A+ Awards for the Architecture +Materials category.

Today’s urban lifestyles are increasingly fast-paced and digital, with more and more time spent within the virtuality of a screen. There seems to be a need for spacial tactility and comfort particularly in dense and high intensity urban fabrics like Manhattan. The contemporary mobile lifestyle is contrasted with the static aspect of our living spaces; man and his built environment are lacking cohesion and interaction.

The project proposes a tactile, interactive, and reconfigurable installation that would serve as urban space for meditation, relaxation and atmospheric therapy.

Designed and built digitally using a conventional material in an unconventional way, ‘tactile fields’, or ‘fy-langes’ is made almost exclusively of packing foam - an inexpensive, recyclable and durable material with interesting physical properties. The interactive installation takes advantage of the translucent, soft and light-weight qualities of the foam and creates a playful experience for all kinds of users.

FY-Langes is responsive to the environment; it moves with the wind, filters light and is shaped by the way people use it. One of the inherent strengths of the system is its flexibility in the way it contours to users' bodies inviting them to interact with it in dynamic ways. FY-Langes, is a reconfigurable system, as its strands can work on their own - other uses include but are not limited to: wall/ceiling installations, furniture, outdoor components.

“You want to touch it.

You want to feel it.

You want to sit on it.

You want to sleep in it.

And it is Beautiful.”

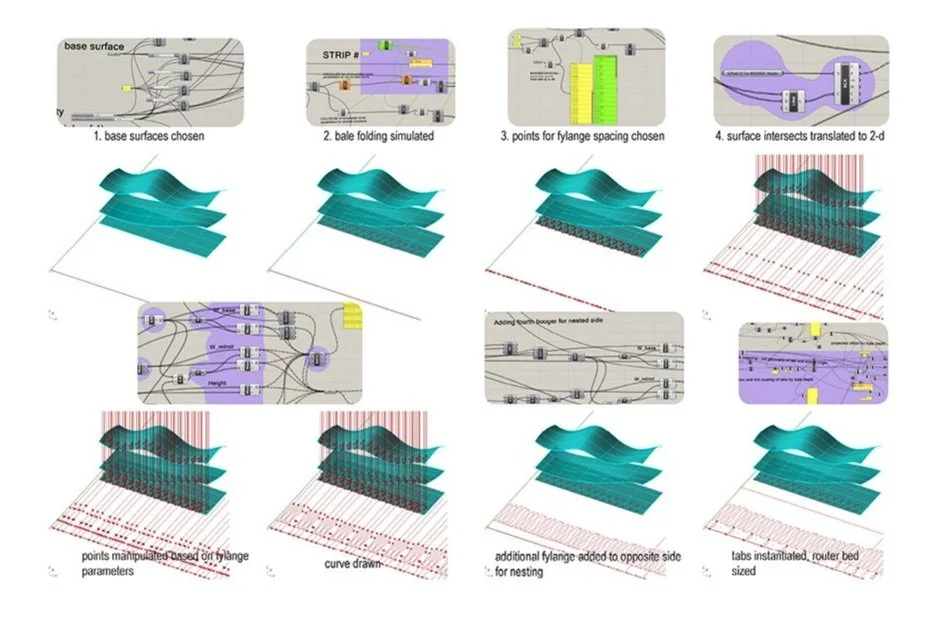

In technical terms, the project also aimed to bridge the digital/material divide by using computation at the center of an iterative experiment between material behavior and form generation, making use of CNC fabrication and parametric design.

From object to field

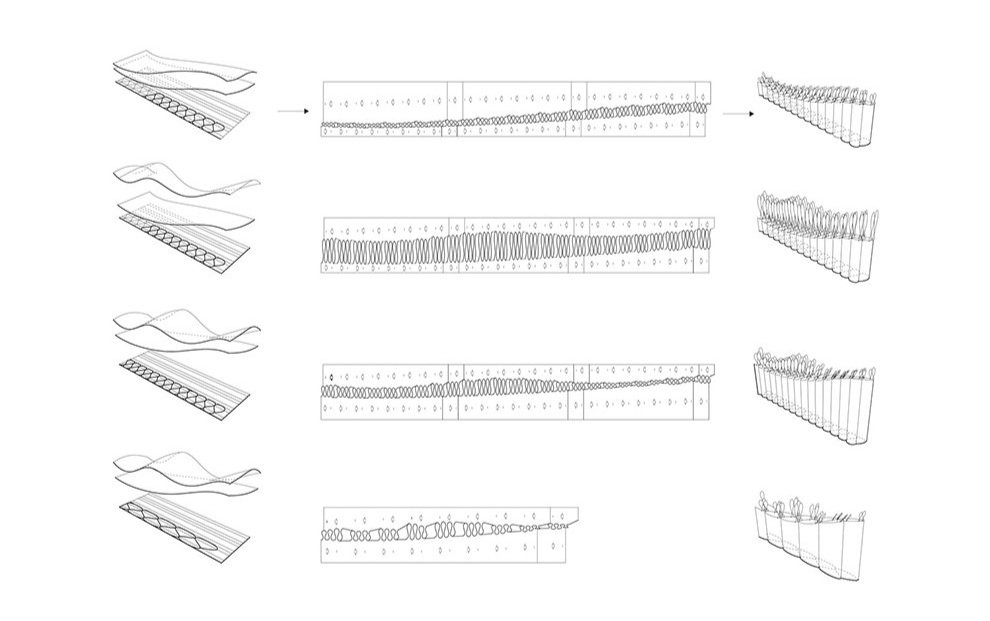

Starting from the dimensions and parameters of packing foam rolls, and adapting the to the ones of the CNC machine used, ‘FY-langes’ had to be designed as a field of aggregated units: parts to be manufactured individually but to be seamlessly assembled to create continuous differentiation. The system consists of repeating strands, each composed of an assembled sequence of bale units.

Continuous differentiation

Each unit is comprised of a folded base and articulated phalanges (or “FY-Langes”). By varying the height of the base versus the height of the phalanges we are able to accommodate many interactive uses. A single sheet of foam generates four nested bales that are custom cut with a CNC router and then folded and tabbed together to create three-dimensional units.

Zero-waste design and manufacturing

The negative of the cut of one bail creates another one. The sinusoidal geometry of the ‘phalanges’ allow for a complete nesting of CNC files of bails: the leftover of one bail is another one. The overall form was designed accordingly to accommodate for the seamless placement of all bails by incorporating a logic of design reciprocity of positive/negative surface mapping.

Embedded joinery system

Tabs and notches are milled into the sheet and each bale is tabbed together, as well as tabbed to the next bale in the strand. The tabbing system allows to build the entire structure using only packing foam and is designed without cut-offs in view of generating close to 0% material waste.

The Grasshopper script offers the possibility to easily customize the form by manipulating three surfaces, which control base, base height and FY-langes height.

Using the three surfaces as input, we wrote a grasshopper script that would output the tabs and notches used to fold each bale. The various parts of the form were also designed and programmed with the nesting strategy in mind. Our largest limitation was the size of the mill bed (4’ x 8’), so we designed the form and curated it to make sure that bales always nested together to ensure that we were gaining the maximum efficiency from any particular sheet. While there is a gradient in the overall form, it does follow a nested strategy, so the change is always proportional.

Diagram illustrating project assembly: roll, cut sheet, nested bales, tab and notch connection and strands.

FY-Langes is an installation designed and produced as part of the Fast Pace/Slow Space technology course at Columbia University’s Graduate School of Architecture, Planning, and Preservation (GSAPP).

Team: Rand Abdul Jabbar, Aisha Alsager, Susan Bopp, Justin Fabrikant, Rikki Frenkel, Joanne Hayek, Eleni-Ilektra Kontoroupi, Mark Pothier, Nicholas M Reiter and Jennifer Romeo.

FY-Langes has received a Special Mention in the Architizer A+ Awards for the Architecture +Materials category.